I was saddened to read a press release for a new wheel mounting guide pin ‘designed to allow the safer mounting and easy alignment of heavy alloy wheels on most common cars that use bolts to fasten to the hub.’ Such a tool will be very useful to take the strain when refitting the wheel and tyre to the car. So, why sad? Well, heavy alloy wheels really is such a shame. There was a time when alloy wheels were sold on the basis of performance enhancement. Now they appear to be mandatory on all new vehicles, (with ‘diamond cut’ and ‘machined face’ soon to be cursed by the owner experiencing the first brush with a kerb stone…….). Unfortunately, ever heavier cars demand strong wheels, and the most cost effective (for the manufacturer) solution is heavy alloys.

Our MGTF demonstrator used MG factory ‘lightweight’ alloys (spun forged by the manufacturer into a mass efficient design). It was always a pleasant surprise when working on the car to remove the wheel with ease. No mounting pin required here. It also gives the vehicle dynamicist a warm feeling, as the damper doesn’t need to work quite so hard to control the unsprung mass. Unfortunately, this wheel is the exception rather than the rule, as we found out the hard way when recently fitting a set of VHS springs and dampers to an MG EV. Very smart alloy wheels, wrapped in rather large (and heavy) 2 ply tyres unfortunately equate to a struggle, muscle strain and grunting to remove and refit. The trend to ever larger SUV styles, EV drive with instant torque and heavy batteries means that the wheel and tyre package must be increased to match – with subsequent tyre wear and particulate emissions that would shame a modern diesel!

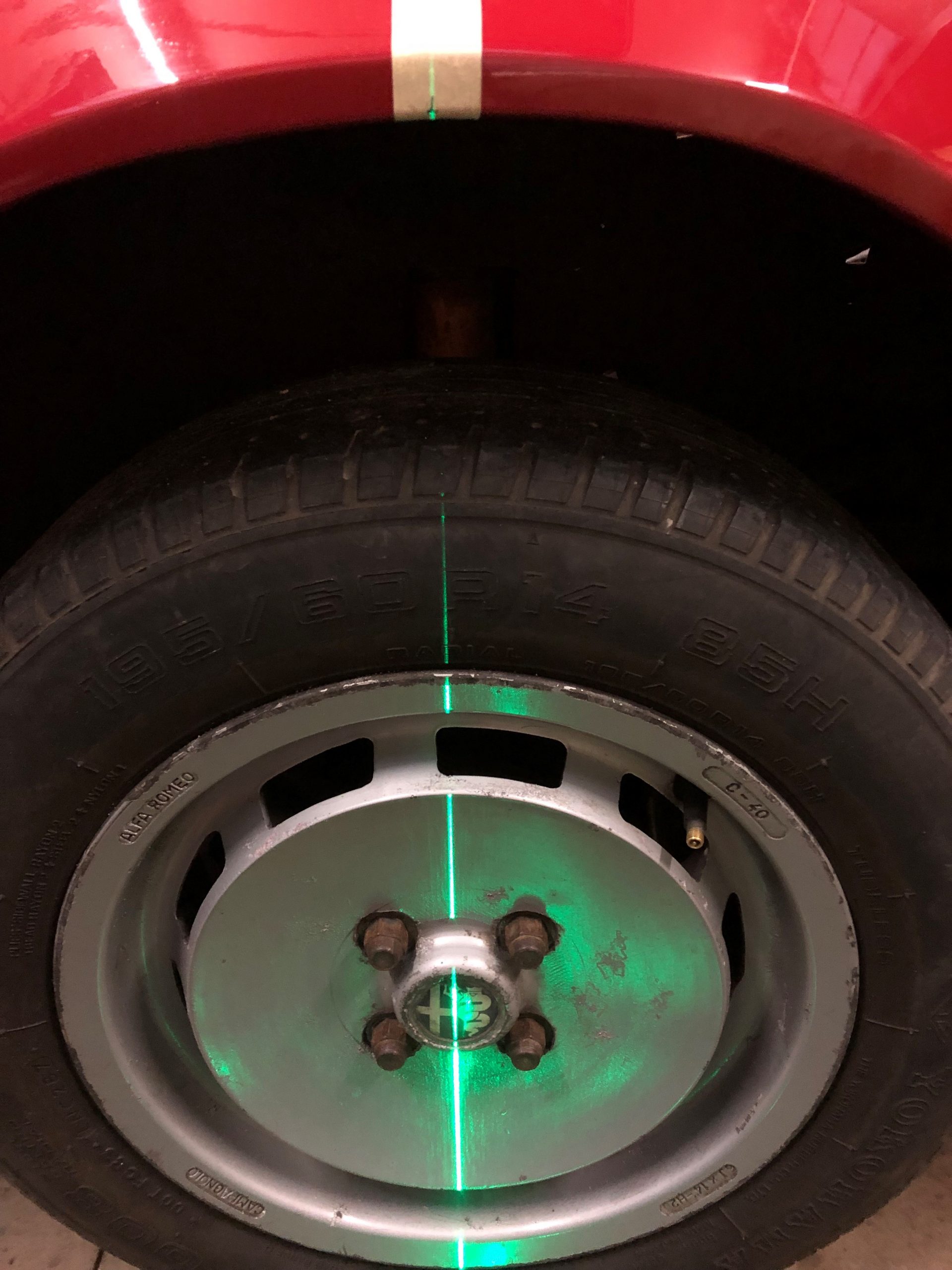

Therefore, it has been a pleasant change to work on an early 1980’s Alfa. The car needed a front ride height correction and subsequent geometry reset. Use of a laser level allowed the ride height to be checked vs the factory specification (which looks at the relative heights of lower arm inboard pivot to outer ball joint). Off with the wheels. Wow! Seriously lightweight. OK, so they are 1980’s small, with similarly petite tyres, but still a surprise. Blessed with torsion bars at the front, careful counting of splines, a few sums and remembering which direction is clockwise, enabled the ride height to be set to match the client’s requirements. The use of double wishbones with a forward-facing tie rod permits easy adjustment of caster. What a beautiful car with delightful engineering features.

Heavy alloy wheels? Needs must, or an unnecessary downward spiral in car design?