Only the driver steers the car. On the face of it, a perfectly sensible statement. But the Chassis Engineer knows otherwise. The car can be subjected to additional steer effects, some deliberately engineered in and some not……

The performance of an axle can be defined by its kinematic and elasto-kinematic properties. The principle measures of front axle geometry are toe, camber and caster (collectively, ‘wheel alignment’). As on most road cars, only toe is designed to be adjustable on the MGF/TF front axle. Other measures that may be discussed are bump steer and compliance steer (which can be introduced by road impact or braking events).

Drivers will probably be aware of the importance of correct wheel alignment in terms of toe (‘tracking’) as this is routinely checked when adverse tyre wear is seen.

So why is anything other than toe important?

Firstly, consider typical complaints:

- Uneven tyre wear

- Pull or drift at constant speed

- Pull or drift under braking

- Unequal steer response or steering effort turning left or right from centre

In addition, there is the much less tangible issue of ‘driver confidence’. Is your car dull to respond, or too nervous? Is it relaxing to drive on the motorway? Does the steering response change as the car loads up in a corner? Does it get too sharp?

Any of these can be caused by front axle geometry problems and all will undermine driving satisfaction.

So, what should be done?

For a standard road car, caster and camber should be within the factory specification. Toe can then be adjusted to nominal and everything will be fine, won’t it?

Well……. the heritage of the F/TF axle is such that achieving close tolerances of caster and camber in production was not possible. The subframe is a complex assembly of pressed and fabricated parts. It carries the double wishbone suspension system which is of narrow separation (vertically, in order to fit within small diameter wheels) and of short wishbone lengths (to permit a narrow track for a front wheel drive compact car, namely the Metro). Therefore, factory specifications were necessarily given rather wide tolerance bands.

If there is a complaint about the performance of the car, consider optimising caster and camber to give balanced values side to side.

But what about bump steer?

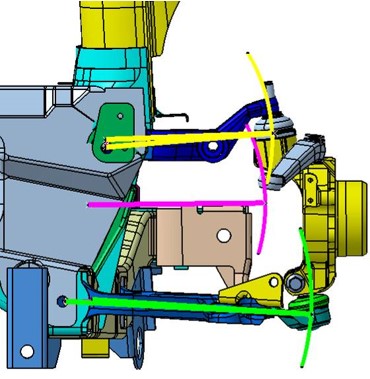

This term is often misunderstood. The basic definition is the amount of steer (toe) change experienced by the road wheel, created when it moves up and down through the vertical suspension travel. (The CAD image shows the kinematic arcs described by the upper arm, lower arm and steering tie rod). An amount of toe change can be desirable for stability, but the key is to carefully develop the characteristic and to be balanced (equal) side to side. For the reasons outlined above, F/TF will often have poor bump steer. An unfortunate result of incorrect caster is the change this makes to the bump steer. Happily, correct caster (usually) gives correct bump steer.

Bump steer can be checked and adjusted once camber, caster and toe have been set correctly. With correct caster, camber, toe and bump steer, then the usual complaints can be solved.

So, the car is perfect? Well not quite.

How about the other elasto-kinematic characteristics which all play a part in defining the dynamic performance of the car? For example, F/TF suffers from a relatively large ground offset. Reducing this can yield benefits (as proven by our VHS Sprint Car), but this will be left for another day. Oh, and don’t forget the rear axle.

Only the driver steers the car……. with a little help from the Chassis Engineer.